분강리 주택 2024.4

Bungang-li House

목조주택의 상품화

교외의 전원주택은 많은 이들이 꿈꾸는 주거 방식이지만, 막상 지어보면 현실적인 어려움이 다수 존재한다. 그중에서도 건물과 관련된 부분으로 보자면, 높은 공사비와 유지관리의 어려움을 들 수 있다. 현장 제작 방식의 비중이 전통적으로 높은 국내 건설업에서는 비용 관리의 개선과 공사비의 효율적인 산정이 여전히 어려운 편이다. 본 프로젝트에서는 북미식 경골 목구조를 토대로 하여, 효율적인 공사비 산정을 위해 극대화된 박스 형태와 외쪽 경사지붕을 도입함으로써 형태와 구법, 비용 산정에 있어 ‘의도적인 심플함’을 계획했다. 결과적으로 유지관리에도 용이하면서, 동일 규모와 스펙의 콘크리트 건축물에 비해 70~80%의 비용으로 건물을 완공할 수 있었다.

대지 현황

대지는 야산을 깎아 만든 소형 주거 단지의 초입에 위치하고 있다. 주변 대지와의 높이차를 활용하여, 설계 초기부터 전망과 뷰(view)를 받아들이면서도 내부에서 360도로 조망할 수 있는 여건을 계획하고자 했다. 이를 위해 2층을 주로 사용하는 공간으로 구성해 쾌적한 실내·외 환경을 조성하고, 다양한 창문 디자인을 통해 외부의 뷰를 다각도로 실내에 끌어들일 수 있도록 설계했다.

업 사이드 다운(Upside-down)형의 실내배치

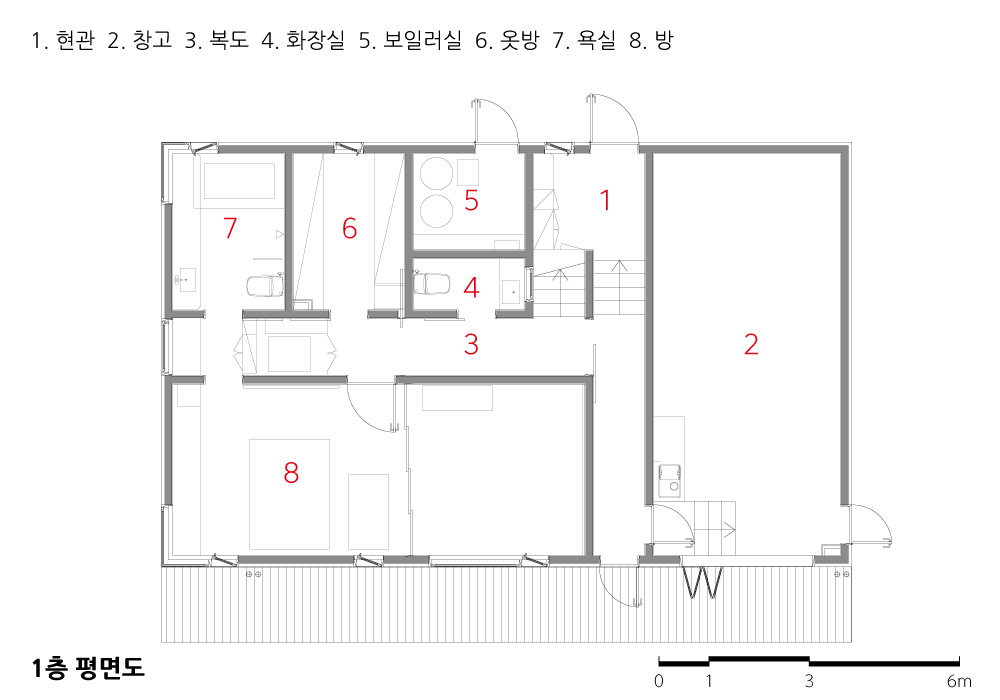

일반적으로는 대지로부터의 접근 편리성을 위해 1층을 L+D+K로 구성하고 2층을 방들로 구성하는데 비해, 본 프로젝트는 주변의 조망을 적극적으로 활용하고자 1층과 2층을 뒤집어서 층별로 배치했다. 이는 경사 지붕 하부 공간을 넓게 활용할 수 있는 장점 외에도, 지붕 하중이 2층 바닥 하중보다 작기 때문에 일반적인 경량 목구조의 스팬 사이즈 한계에 비해 훨씬 더 큰 공간을 연출할 수 있는 이점이 있다.

유지 관리의 용이성

주택의 상품화에 있어 유지관리의 용이성은 매우 중요하다. 심플한 외관은 합리적인 공사비용을 도출할 뿐 아니라, 불필요한 하자 요인을 초기부터 제거해 유지관리에 있어서도 용이하다. 아울러 외쪽 경사 지붕을 도입하고 벽체보다 처마를 의도적으로 돌출시켜 벽체 오염을 최대한 줄이고자 했다. 이웃 나라에서 수십 년간 검증된 세라믹 사이딩을 주요 외장 마감재로 사용하여, 노후화를 줄이면서도 강우 시 쉽게 오염물질이 씻겨 나갈 수 있도록 했다.

상품으로서의 주택

아파트 등의 공동주택에 비해 단독주택 시장은 유지관리나 공사비 산정에 어려움이 있으며, 이는 단독주택 시장의 저변을 넓히는 데 있어서 큰 장애물로 지적되고 있다. 합리적인 구조 공법을 도입하고, 효율적인 공사 방식과 비용 컨트롤이 가능하면서도 유지 관리가 용이하도록 단독주택 시장을 보다 산업화시킬 필요가 있다. 목구조 방식은 현장 타설 콘크리트 구조에 비해 일관된 품질을 유지하면서도 대량 생산이 가능하고 비용을 낮출 수 있어 상기의 목표에 유리한 부분이 있다. 이처럼 ‘상품으로서의 주택’이 늘어날수록 단독주택 시장의 확산 속도가 빨라질 것이며, 우리 사회의 주거 문화도 다양하고 풍요로워질 것이라 생각한다.

Commercializing Wooden Houses

The commercialization of wooden houses is a dream residential style for many living outside urban centers, yet building one often comes with numerous practical challenges. Among these, high construction costs and maintenance difficulties stand out. In the local construction industry, where on-site fabrication methods traditionally dominate, managing costs and efficiently estimating construction expenses remain challenging tasks. This project, based on the North American light-frame wood structure, aimed for “intentional simplicity” in form, construction method, and cost estimation by maximizing the box shape and introducing a sloped roof, which also facilitated maintenance and allowed the building to be completed at 70-80% of the cost of a comparable concrete structure.

Site Conditions

The site is located at the entrance of a small residential complex carved out of a mountainside. From the outset, the design aimed to capitalize on the elevation difference with adjacent lands to incorporate views and panoramas from within the building, ensuring a 360 degree perspective. This was achieved by designing the main living spaces on the second floor, creating comfortable indoor and outdoor environments and designing various windows to bring in the exterior views from multiple angles.

Upside-Down Interior Layout

Unlike the common practice of designing the ground floor for accessibility and reserving the second floor for bedrooms, this project inverted the floors to actively utilize the surrounding vistas. This approach not only leverages the spacious area under the sloped roof but also benefits from the lighter roof load compared to the second floor load, allowing for larger spaces than what is typically achievable with light wood structures.

Ease of Maintenance

Ease of maintenance is crucial for commercialized housing. A simple exterior not only results in reasonable construction costs but also minimizes potential defects from the start, easing maintenance efforts. Additionally, the introduction of a sloped roof and intentionally extending the eaves beyond the walls helps minimize wall contamination. Using ceramic siding, a material proven over decades in neighboring countries as the primary exterior finish, reduces aging and allows for easy cleaning of contaminants during rain.

Housing as a Product

The single-family home market, unlike the apartment or communal housing sector, faces challenges with maintenance and cost estimation, posing significant barriers to market expansion. There’s a need to industrialize the single-family housing market by adopting rational construction methods, efficient building techniques, and cost control, while ensuring ease of maintenance. Wood structure methods, capable of maintaining consistent quality and allowing mass production at lower costs compared to on-site concrete structures, are advantageous for achieving these goals. As “housing as a product” becomes more common, the single-family housing market will likely expand more rapidly, enriching and diversifying our society’s residential culture.

| 분강리 주택 설계자 | 이양재 _ 엘리펀츠 건축사사무소 건축주 | 최의성 감리자 | 이양재 시공사 | 최의성 설계팀 | 정규영 대지위치 | 충청남도 공주시 탄천면 분창양달길 19-4 주요용도 | 단독주택 대지면적 | 700.00㎡ 건축면적 | 112.19㎡ 연면적 | 199.4㎡ 건폐율 | 16.03% 용적률 | 28.49% 규모 | 2F 구조 | 철근콘크리트구조, 목구조, 경량목구조 외부마감재 | 세라믹사이딩, 목재사이딩 내부마감재 | 석고보드위 도장, 마모륨 마감 설계기간 | 2023. 03 – 2023. 06 공사기간 | 2023. 07 – 2023. 12 사진 | 최진보 전문기술협력 구조분야 : 조성우 _ 조 구조기술사사무소 |

Bungang-li House Architect | Yi, Yang Jae _ Studio-Elephants Client | Choi, Eui-Sung Supervisor | Yi, Yang Jae Construction | Choi, Eui-Sung Project team | Jeong, Gyu-yeong Location | 19-4, Bunchangyangdal-gil, Tancheon-myeon, Gongju-si, Chungcheongnam-do, Korea Program | Single house Site area | 700.00㎡ Building area | 112.19㎡ Gross floor area | 199.4㎡ Building to land ratio | 16.03% Floor area ratio | 28.49% Building scope | 2F Structure | Light-frame wood structure Exterior finishing | Ceramic siding, Wood siding Interior finishing | Paint for gypsum board, Linoleum floor Design period | Mar. 2023 – Jun. 2023 Construction period | Jul. 2023 – Dec. 2023 Photograph | Choi, Jin-bo Structural engineer | Jo`s Engineers |