수퍼빈 아이엠팩토리 2024.6

SuperBin im_factory

아이엠팩토리, 공장 같지 않지 않은 공장, 화성시 우정읍 화산리에 자리 잡은 친환경 재활용 공장의 이름이다. 건축 용도상 자원순환시설, 폐기물 재활용시설인 아이엠팩토리는 폐기물 공장이지만 공장처럼 보이지 않고 오히려 미술관에 가까워 보이는 건축물로 기존의 패러다임을 바꾸고자 했다. 버려지는 쓰레기를 다시 소재로 활용할 수 있도록 선별 수집 시스템과 물류 인프라를 재설계하여, 모인 폐플라스틱이 고품질 플레이크(FLAKE)로 제조돼 이윤이 되는 새로운 방식의 순환경제를 구축하는 새로운 유형의 건축물이다.

디지털 기술이 접목된, 차별화된 친환경 재활용 공장

쓰레기가 돈이 되고 재활용을 놀이라는 일상의 문화로 만들려는 수퍼빈은 쓰레기와 문화라는 소재를 두고 인공지능과 로보틱스 기술, 빅데이터의 기술을 활용해 새로운 가치를 만드는 기업이다. 아이엠팩토리는 쓰레기로 시작되는 새로운 순환경제 구축 중 하나로 개발된 네프론을 통해 선별 수집된 PET를 디지털 기술이 접목된 자체 기계를 통해 순도 높은 플레이크로 가공하는 재활용 공장이다. 기존 폐기물 공장이 가지고 있던 먼지, 소음, 폐수, 악취 등의 문제를 4차 산업이 적용된 로봇과 기계를 통해 해결하여 폐기물 공장의 역할을 할 뿐 아니라 재활용의 과정을 전시, 관람의 영역으로 확장시키고 나아가 문화적 콘텐츠까지 수용할 수 있는 건축물로의 차별화된 계획이 요구되었다. 가까이 가고 싶지 않은 혐오시설을 보여주고 싶은 장소인 복합문화시설로 만들기 위해 외부 자연과 내부는 어떤 관계를 맺을 것인지, 자연을 어떻게 건축물에 유입할지 고민하며 설계를 진행했다.

U자 형태의 창의적인 배치

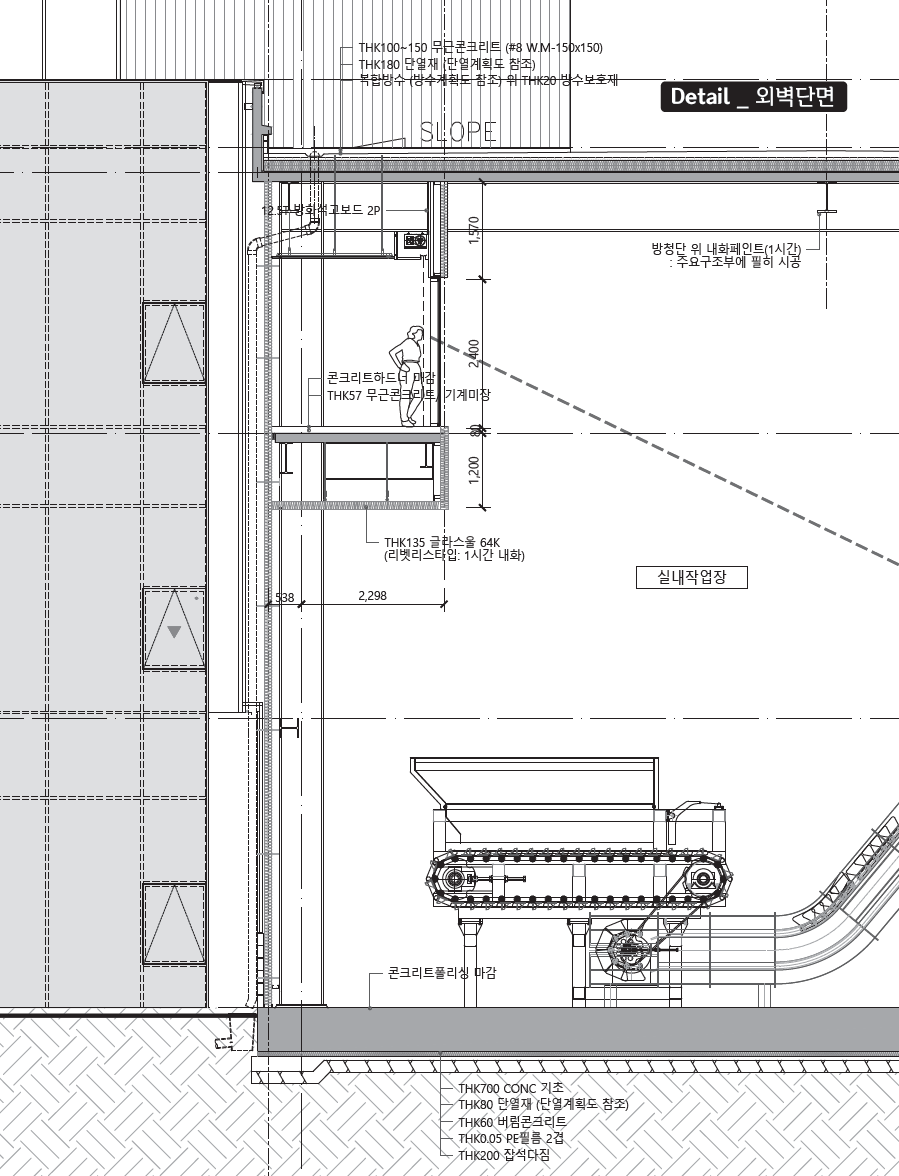

기본적인 폐기물 공장의 기능을 수행하기 위해 기계설비가 들어갈 대공간의 확보가 필요했다. 수집된 PET는 약 150미터 길이로 특수 제작, 배치된 기계들에 의해 전처리-분쇄-세척-건조-선별 공정을 거쳐 정화된 제품 플레이크가 된다. 9,886제곱미터 너비의 제약된 대지 안에 기계 배치를 위한 최소 15미터 너비와 150미터 길이의 공간을 확보하기 위해 U자 형태의 건물을 배치했다. 공정을 따라 일반적인 一자 건물이 아닌 U자의 배치는 새로운 기능을 더 효율적으로 수용할 수 있는, 전에 없던 새로운 건물이 되었다. 긴 작업 공간으로 1개 층에 안정적으로 기계가 가능하고, U자의 윗면으로 차량의 동선이 정리되었으며, U자의 안쪽으로 사무·전시·문화 공간이 집중되어 한눈에 150미터가량의 공정을 쉽게 파악할 수 있는 명쾌한 건물이 되었다.

자연을 유입하기 위한 진입마당과 불규칙한 사각의 개구부

U자 형태 내부의 진입마당이 아이엠팩토리의 메인 인상이자 방문자의 동심과 호기심을 자극하는 머물고 싶은 친근한 공간이 되기를 기대했다. 공간의 처음 시작인 진입광장에서 지그재그로 된 동선으로 경험을 유도하고, 공장 내부를 창으로 볼 수 있는 공장을 전시하는 공간이 되도록 했다. 진입광장 조경 계획은 기존의 아파트 철거 현장에서 버려진 나무를 재사용·배치해 재활용과 버려지는 자원에 대해 생각할 기회를 제공한다. 진입마당을 마주하는 창은 커튼월로 계획해 진입마당과 시각적인 소통을 할 수 있게 했다. 그 외에 개구부는 층에 따라 일률화되지 않은 불규칙한 정사각형의 개구부로 저층부에서는 공장의 일부의 작업을 전시하고 바라볼 수 있는 포토존이 되고, 공장의 내부에서는 빛과 바깥의 자연환경 조경을 적극적으로 유입하고 시시각각 변하는 빛과 그림자의 움직임과 조경을 끌어들여 공장 작업자들이 작업장 내에서 외부의 변화를 누릴 수 있도록 유도했다.

시민들이 참여하는 재활용 복합문화공간

폐기물 공장으로 플레이크 생산을 넘어 관람, 콘텐츠 개발로 참여할 수 있는 재활용 문화가 확장되는 장소를 제공하기 위한 복합문화공간을 계획했다. 새로운 콘셉트의 공간, 친환경 쓰레기 순환 경제와 관련된 재활용 공정 견학과 업사이클링 체험 등 다양한 콘텐츠 제공으로 쓰레기가 가치가 되고 재활용이 친근해지는 의미 있는 공간으로 인식돼 지역 주민과 방문자들에게 사랑받기를 바란다.

“Im factory” is the name of an environmentally friendly recycling facility located in Hwasan-ri, Ujeong-eup, Hwaseong City. Although it is a waste management facility, “Im factory”aims to challenge the conventional paradigm by presenting itself as a building that doesn’t resemble a typical factory, but rather resembles an art museum. The facility, designated as a resource recycling related facilities, is a new type of building that establishes a new form of circular economy. It achieves this by redesigning the sorting and collection system, as well as the logistics infrastructure, to enable the reuse of discarded waste materials. Specifically, the facility focuses on the collection and processing of post-consumer plastic waste, transforming it into high-quality flakes that can be economically viable.

An environmentally friendly recycling facility

incorporating digital technology.

SuperBin is a company that aims to transform waste into money and recycling into a daily culture of play. It utilizes artificial intelligence, robotics technology, and big data to create new value from the materials of waste and culture. “Im Factory”, as part of the establishment of a new circular economy starting from waste, is a recycling facility that processes selectively collected PET into high-purity flakes through its own digitally integrated machines, using Nepron, a material developed for this purpose. By incorporating robots and machinery from the fourth industrial revolution, “Im Factory” not only addresses issues such as dust, noise, wastewater, and odor commonly associated with waste facilities but also expands the recycling process into an exhibition and viewing area, even accommodating cultural content. The architectural design required a differentiated approach to transform the facility from a place associated with aversion into a complex cultural facility where people would want to visit. The relationship between the external natural environment and the interior space was carefully considered to incorporate nature into the building and create a harmonious connection between the two.

The creative arrangement of a U-shaped layout

To accommodate the necessary machinery for the basic functions of a waste facility, a spacious area needed to be secured. The collected PET goes through a preprocessing, grinding, washing, drying, and sorting process using specially designed and arranged machines, resulting in purified flakes as the final product. To ensure the placement of machines within the limited 9,886 square meters of land, a U-shaped building layout was adopted, providing a minimum width of 15 meters and a length of approximately 150 meters. This U-shaped arrangement, following the production process, created a new type of building that can efficiently accommodate additional functionalities. The elongated workspace allows for stable machine operation on a single floor, while the upper side of the U-shape organizes the movement of vehicles. Inside the U-shape, spaces for offices, exhibitions, and cultural activities are concentrated, allowing for easy observation of the approximately 150-meter production process at a glance. The resulting building is clear and easily comprehensible.

Entrance courtyard and irregular square aperture

I expected the U-shaped inner entrance courtyard to become a welcoming space that stimulates the curiosity and nostalgia of visitors, leaving a lasting impression of the “Im Factory”. Starting from the entrance plaza, which serves as the initial point of the space, a zigzagging pathway is designed to guide the experience and provide a view of the factory through windows, creating a space that showcases the factory. The landscaping plan for the entrance plaza offers an opportunity to contemplate recycling and discarded resources by incorporating reused wood from demolished apartments. The windows facing the entrance courtyard are planned as curtain walls, allowing visual communication with the courtyard. Other openings are irregular square shapes that vary on each floor. The lower floors feature exhibition spaces where parts of the factory’s operations are displayed, providing photo zones for observation. The interior of the factory actively incorporates light and the surrounding natural environment through landscape design, utilizing the changing movements of light and shadows and integrating the scenery. This design aims to enable factory workers to experience the external changes while working within the facility.

A multifunctional cultural space

for citizen participation in recycling.

We have planned a multipurpose cultural space that goes beyond waste facilities and Flake production to provide a place where recycling culture expands through participation in viewing, content development, and more. With a new concept, we aim to create a meaningful space where local residents and visitors perceive waste as valuable and recycling becomes familiar through various content offerings such as guided tours of recycling processes and upcycling experiences. We hope that this space will be loved by local residents and visitors alike.

| 수퍼빈 아이엠팩토리 설계자 | 김이홍 _ (주)건축사사무소 김이홍아키텍츠 건축주 | 수퍼빈(주) 감리자 | (주)건축사사무소 수목21 설계팀 | 김현주, 강정구 설계의도 구현 | (주)건축사사무소 김이홍아키텍츠 대지위치 | 경기도 화성시 우정읍 사기말길 27번길 87-41, 87-39 주요용도 | 자원순환관련시설, 제 2종근린생활시설98 대지면적 | 9,886.00㎡ (A,B동) / 1,831.00㎡ (C동) 건축면적 | 3,710.50㎡ (A,B동) / 184.40㎡ (C동) 연면적 | 5,336.59㎡ (A,B동) / 184.40㎡ (C동) 건폐율 | 37.53% (A,B동) / 10.07%(C동) 용적률 | 53.52% (A,B동) / 10.07%(C동) 규모 | 4F(A동) / B1F - 1F(B동) / 1F(C동) 구조 | 일반철골구조 외부마감재 | 금속패널, 시멘트블록 내부마감재 | 금속패널, 석고보드 위 페인트 설계기간 | 2021. 04 – 2021. 10 공사기간 | 2021. 11 – 2022. 11 사진 | 홍기웅 구조분야 | 건축구조연구소 다우 기계설비·전기·소방분야 | 선이엔지 |

SuperBin im_factory Architect | Kim, Leehong _ Leehong Kim Architects Client | SUPERBIN Supervisor | Soomok21 Architects Project team | Kim, Hyun Ju / Ghang, Jeongoo Design intention realization | Leehong Kim Architects Location | 87-41, 87-39 Sagimal-gil 27beon-gil, Ujeong-eup, Hwaseong-si, Gyeonggi-do, Korea Program | Resource recycling-related facilities Class 2 neighborhood living facilities Site area | 9,886.00㎡ (A,B) / 1,831.00㎡ (C) Building area | 3,710.50㎡ (A,B) / 184.40㎡ (C) Gross floor area | 5,336.59㎡ (A,B) / 184.40㎡ (C) Building to land ratio | 37.53% (A,B) / 10.07%(C) Floor area ratio | 53.52% (A,B) / 10.07%(C) Building scope | 4F(A) / B1F - 1F(B) / 1F(C) Structure | Steel-frame structure Exterior finishing | Steel panel, Hollow concrete blocks Interior finishing | Steel panel, Paint finish above Gypsum board Design period | 2021. 04 – 2021. 10 Construction period | 2021. 11 – 2022. 11 Photograph | Hong, Kiwoong Structural engineer | Architecture Structural Research Institute DAWOO Mechanical·Electrical·Fire engineer | Suneng |