2023. 2. 1. 09:17ㆍ회원작품 | Projects/Office

SAMIL BUILDING RENOVATION

3.1빌딩 Concept

글. (주)건축사사무소 원오원아키텍스

1. URBAN

1-1. 정면성의 회복

파사드는 크게 기준층과 저층부, 그리고 옥상으로 나누어 계획하였다. 기준층은 3.1빌딩의 기존 파사드를 최대한 유지하되 에너지법과 건축법을 만족시키면서 약간의 변형을 주었다. 돌출 I빔은 플레이트용접 방식으로 기존의 R값이 보이지 않게 섬세한 변형을 주었으며, 내부 멀리언 바는 기존보다 얇고 길게 프로포션(비율)을 조정하여 I빔의 섬세함과 연속적인 느낌을 부여하였다. 북측의 코어박스는 전면의 유리커튼월 재료와 모듈과의 관계를 고려해 금속판넬로 디자인하되, 금속돌출 리브를 북측면 한 면에만 두어 섬세한 전면 디자인의 연속성을 유지하려고 했다. 그리고 기존 엘리베이터 홀에 빛이 없어 어둡고 조망이 안 되는 구조를 해결하고자 해당 면에 오프닝을 제안 후 디자인하였으며, 구조적인 문제로 인해 상부층 일부만 계획되었다.

옥상은 추가적인 설비로 인해 일부 옥탑 구조물의 계획이 필요했기에, 기존에 없는 돌출 구조물이 필요하였다. 기본적인 원칙은 기존의 원형을 최대한 유지하기 위해 기존 코아와 매스를 최대한 연계하고 외벽 마감에서 셋백해 디자인하였다. 재료의 마감은 기준층의 수직 멀리언의 디자인 요소를 가져와 알루미늄 루버로 계획하였다.

1-2. 공공성과 개방성

3.1빌딩 저층부의 공공성 회복은 파사드의 복원만큼 중요한 가치를 지니고 있다. 과거 50년의 가치를 지닌 건물이 지금부터 50년 이후의 미래가치 또한 지녀야 했기에, 기존에 세상과 단절돼 있었던 장벽들을 하나씩 걷어내고 공공성을 회복하는 개념들이 필요했다. 먼저 지하층은 층고가 너무 낮았고, 빛의 유입도 없어 거의 죽은 공간으로 사용되고 있었다. 1.5m를 올라가야 하는 1층 레벨을 고려해 최소한의 계단으로 지하 진입이 가능해지고 공간도 훨씬 밝아질 수 있도록 전면 대지경계선에서 3m 후퇴선을 기준으로 25m×7m의 선큰을 계획하였다. 현재 선큰을 중심으로 기존 건물 쪽이 아닌 반대쪽 공간은 기존 지하 1층 레벨보다도 낮고 동선도 길어 거의 창고로 쓰이고 있었다. 선큰을 통한 임대면적 손실은 있었지만, 지하공간이 모두 가치 있게 변화되는 개념을 발주처에서도 긍정적으로 이해하고 적극 수용하였다. 해당 공간의 낮은 바닥 레벨은 외부 조경을 바라보는 사람들의 눈높이를 비일상적인 레벨로 만들면서 레스토랑으로 이용할 수 있도록 제안한 부분도 이해도를 높일 수 있었다.

1층 기단의 경우 기존에는 계단이 있어서 명료하게 풀리지 않아 하나의 기단으로 묶어 풀어낼 방법이 필요했다. 선큰 - 1층 외부공간 - 기단을 하나의 그라운드 스케이프로 해석해 기존의 어두운 대리석 대신 밝은 색상의 바닥과 연계될 수 있는 화강석(사비석)으로 디자인하였으며, 1층 외부공간은 100×100각 사고석으로, 나머지 선큰과 1층 기단 부분은 전통 기단의 느낌처럼 보일 수 있게 1200×430 크기의 막힌줄눈 방식으로 계획하였다. 코너는 모두 통석으로 엇갈리게 처리하여 자연스러운 디테일로 풀었으며, 바닥에서 살짝 띄운 하단에 조명을 설치하여 그라운드 레벨과의 디테일을 가볍게 만들었다. 계단하부로 연결되는 지하층 급배기 그릴은 모두 하부석재 오프닝 방식으로 처리하여 외부에서 그릴이 보이지 않게 개구면적을 맞추면서 기단부가 그릴로 인해 디자인이 훼손되지 않게 하였다. 또한 기단의 난간은 저철분 유리로 계획하여 파사드와 기단의 분리가 명확히 보이게 하였다.

3.1빌딩의 기존 1층 입면은 2층과 분리되어 있어서 저층부의 개방성을 확보하기 어려운 상황이었다. 해서 1층 입면 커튼월을 보 바깥으로 빼고 1, 2층의 입면을 연결해서 개방성을 높였다. 2층 트랜썸은 바닥 레벨보다 다운시켜 2층 바닥에서 외부를 볼 때 바닥에 트랜썸 라인이 보이지 않게 개방감을 만들었으며, 현장갈기 마감인 테록시 마감수평라인을 깨끗하게 유지할 수 있었다. 3개 층으로 이루어진 저층부(지하1∼2층)는 기존의 좁고 답답하며 어두운 공간을 개방감 있게 풀어줄 디자인과 그라운드 레벨에서 외부와의 소통을 위해 몇 가지 장치를 디자인하였다.

첫째, 2층 천장을 광천장으로 디자인해 저층부와 고층부를 가볍게 분리하여 기존 그리드 디자인의 원형은 유지하고, 천장 전체가 밝아지도록 디자인하였다.

둘째, 1, 2층 저층부와 접한 코아측 긴 수평벽체 상단에 반사체를 사용하여 실내나 외부에서 천장면이 연속적으로 확장되게 보여지도록 디자인하였으며, 디테일에 깊이감을 더하기 위해 어두운 바탕면을 만들고 일정간격 이격한 후 투명유리를 계획하는 방법으로 리플렉션 효과를 연출했다.

셋째, 원오원아키텍스에게 ‘그라운드 스케이프’는 매우 중요한 키워드이다. 주변 지형을 잘 고려해야 하는 측면도 있지만, 그라운드 스케이프는 건물을 둘러싼 사람과 문화, 자연, 역사, 풍경을 모두 담는 개념이므로 지하 1층과 지상층을 연결하여 공간을 주변에 적극적으로 개방한다면 다음 세대에 새로운 길을 만들어 줄 수 있지 않을까 고민했다. 회전 계단으로 세 개 층을 연결한 것은, 이 장소에 각 층마다의 수평적인 움직임과 함께 수직적인 움직임도 만들고 싶었기 때문이다. 또 공공에 열리는 장소이기에 경쾌한 분위기를 만들고 싶었다.

2. HISTORY _ 김중업 / 미스 반 데어 로에

2-1. 시그램 빌딩

시그램 빌딩은 공간적으로 저층부 공간에 수평적 깊이가 있었다면, 3.1빌딩은 좁은 대지와 건축물 구조의 한계로 인한 도시와의 수평적 관계를 수직적으로 재해석하여 적용하면서 도시와 단절되었던 3.1빌딩에 새로운 생명력을 부여해 그 가치를 이어가려고 하였다. 또한 기존의 대리석으로 마감한 저층부 외부 마감을 금속과 유리 커튼월로 새롭게 해석하면서, 미스의 디테일을 일부 차용하였다. 기둥 부분의 디테일에는 I빔을, 방풍실 부분에는 디귿자(ㄷ) 형태의 앵글을 디자인 요소로 사용하여 저층부와 기준층이 외부에서 볼 때 하나의 디자인 언어로 이어질 수 있도록 계획하였다.

2-2. 헤리티지

근대문화유산으로서의 3.1빌딩에 대한 헤리티지는 저층부의 중요한 건축 및 인테리어 요소로 디자인되었다.

첫째, 원형 계단을 위한 보이드를 계획하여, 남겨진 보와 주변에 슬라브 단면 및 기둥 2개소를 마감하지 않고 원형의 콘크리트 구조체를 자연스럽게 드러내어 새로운 마감재와 이질감 없이 자연스럽게 보일 수 있도록 했다. 둘째, 1층 부출입구에 기존 커튼월로 벽체 일부를 디자인하여 3.1빌딩의 상징인 커튼월을 자연스럽게 사람들의 눈높이에서 볼 수 있도록 하였으며, 마지막으로 50년 전 준공석과 현재의 준공석을 나란히 전면에 배치하여 역사의 단면이 한눈에 보일 수 있도록 하였다.

3. RENOVATION

3-1. 기준층

전용공간에서의 최대 관심사는, 층고를 높이는 디자인과 그로 인해 파생되는 다른 요소들과의 관계를 정리하는 일이었다. 우선 외주부와 내주부로 나누었다. 외주부는 외부에서 볼 때 통일성 있는 조명이 보이도록 개방감 있게 만들고자 하였다. 내주부는 코아와 연계하여 일부 천장을 계획해 설비를 최대한 해당 부분에 집약시키고 추후 회의실이나 칸막이 벽체가 설치될 수 있는 계획을 제안하였으며, 다른 요소들과의 관계는 아래의 몇 가지 디테일을 통해 해결하였다.

첫째, 커튼월과 만나는 최소한의 커튼박스용 천장만 계획하여 커튼월과 천장의 관계를 정립한다.

둘째, 노출천장의 조명은 커튼월 간격(900㎜)을 기준으로 1,800㎜마다 계획하고, 스프링클러는 조명과 일체로 디자인하여 최대한 천장의 개방감을 유지한다. 조명의 경우 외부에서도 동일하게 보일 수 있도록 커튼월과의 이격거리를 조절한다.

셋째, 천장이 계획된 낮은 부분의 천장은 노출부분의 조명라인과 라인을 맞추고, 일체형으로 디퓨져 계획을 한다.

천장의 노출 컬러는 커튼월과의 공간감을 고려해 어두운 색상으로 톤을 맞춘 다음, 기둥과 벽, 낮은 천장, 노출 조명은 흰색 그리고 바닥은 밝고 따듯한 베이지톤으로 조절하여 전체 톤을 세심하게 컨트롤하였다. 또 공용공간은 북쪽 한 면을 반사체로 계획하여 저층부와 동일한 리플렉션 효과로 개방감을 확보하였다.

3-2. 저층부

저층부는 외부공간과 기준층과의 연속적인 관계에서 계획되었으며, 과거의 도면을 통해 에스컬레이터 위치를 복원하여 2층에 로비를, 1층에는 앵커테넌트(핵심 점포)를 만들고 3개 층을 수직적으로 연결하는 동선 계획이 출발점이 되었고 그 이후 각각의 건축적 요소들을 디자인하였다.

천장의 경우 기준층 커튼월 라인을 기준으로 저층부 기둥 및 커튼월 기준선을 만들었고, 이후 해당 라인에 따라 1.8m×1.8m 그리드를 만들어 천장 디자인을 완성하였다. 1, 2층 천장은 같은 사이즈를 가지고 있지만, 2층은 그리드면 자체가 광천장이 되고 테두리가 디퓨져로 만들어진 반면 1층은 테두리가 조명이고 면은 흡음재로 만들어져 하나의 그리드로 두 가지 디자인을 만들었다. 이 계획은 기존의 3.1빌딩과 미스의 그리드 조명을 재해석한 디자인으로, 두 층 모두 천장면에서 조명이 돌출되지 않도록 플랫한 면을 만들어 개방감을 확보하고, 스프링클러 및 감지기를 그리드 교차점에 설치하여 일체감 있는 천장 디자인을 계획하였다.

바닥은 외부 화강석의 톤과 유사한 테라죠 현장 갈기 방식으로 프레임 없이 넓은 하나의 면이 외부에서 연속적으로 이어지게 계획하였다. 벽체도 같은 톤으로 일체감 있게 계획하여 천장과 커튼월의 선적인 요소에 대응해 면으로 구성하였다. 벽체 상단은 유리 반사체로 디자인하였으며, 내주부 기둥은 금속 반사체로 계획하여 통일성과 개방감을 확보하였다.

원형계단은 철판 자체 구조로 해석하는 디자인을 제안하였고, 별도의 마감 없이 계단 바닥판의 요철이 드러나게 하여 개방감과 구조미를 드러냈다. 원형 계단 주변 오프닝은 저철분 난간으로 디자인하여 원형계단의 내외부에서 개방감이 돋보일 수 있게 하였다.

3.1빌딩 리노베이션_근대화의 상징 3.1빌딩의 원형 보존과

지속 가능한 랜드마크 타워로의 재탄생

글. (주)정림건축 종합건축사사무소

1970년 준공되어 지금까지 50여 년간 관철동에 자리한 3.1빌딩은 노후화로 인해 현대에 요구되는 오피스 그레이드와 경쟁하기에는 부족한 면이 있었다. 그럼에도 불구하고 3.1빌딩은 서울에 몇 안 되는 큰 용적률을 가진 건물로서 부동산 가치로는 설명할 수 없는 매력이 있다. 오랜 시간 동안 우리의 근대화 시기를 정면으로 관통해온 상징성과 그에 따른 수많은 이야기가 담긴 건물이다. 근대화의 상징, 근현대 건축자산, 대한민국이 낳은 김중업이라는 거장의 작품, 우리나라 최초의 고층 빌딩, 3.1빌딩의 모티브가 된 시그램 빌딩의 이야기 등, 건물과 관련해 많은 이야기를 만들어 왔다. 그만큼 약 50년 된 이 건물과 관련한 스토리는 강력함을 지니고 있다.

이 프로젝트는 이러한 3.1빌딩이 주는 오래된 아름다움을 현대적 감각의 디자인으로 녹여냄과 동시에 현대 오피스가 요구하는 기능, 그리고 우리나라 중심 종로에 매우 독특한 장소성을 가진 새로운 건물로 다시 태어나길 바라는 마음으로 시작되었다. 이 건물이 주는 독특한 매력을 알아본 건축주의 안목과 리노베이션 프로젝트에 참여한 많은 이들이 한 마음으로 염원하고 그려온 그림이 지금의 3.1빌딩의 모습이다.

1970년에 완공된 삼일로 빌딩은 그로부터 15년 후 여의도에 63빌딩이 들어설 때까지 국내에서 가장 높은 건물이었으나 50여 년이 경과되어 시설의 노후화가 급격히 진행됨에 따라 우리의 기억에서 점차 잊혀가고 있었다. 우리는, 근대화의 상징이었던 청계고가가 사라지고 주변 가로가 변화되고 있는 모습에서 3.1빌딩의 재탄생 가능성을 발견했다. 즉, 설계자인 김중업 건축사의 발자취를 따라가며 3.1빌딩에 담겨있는 가치를 발견하고 ‘원형을 지키면서 지나온 시간만큼 미래에도 지속 가능한 건축물’로서 과거의 명성을 되찾을 수 있도록 노력했다.

Reading of site_청계고가도로의 철거

3.1빌딩이 건축될 당시와 지금을 비교하자면 가장 달라진 부분은 바로 청계천이다. 3.1빌딩의 입지를 선정할 당시 많은 사람들이 한강 이남지역을(지금의 강남) 최적의 장소로 제안했다고 한다. 하지만, 김두식(3.1빌딩 건립자)는 지금의 위치가 청계고가의 건설, 지하철 1호선의 건설계획으로 교통의 중심이 될 것이라고 판단했다고 한다. 실제로 완공 당시 대한민국에서 가장 높은 건물이었던 3.1빌딩은 세운상가, 청계고가도로와 함께 종로구의 가장 대표적인 명물이었다. 그만큼 지금의 입지 선정에 가장 중요한 요인은 청계고가도로였다.

하지만 지금은 이런 청계고가도로가 철거되고 청계천이 복원되면서 과거와 현대가 공존하는 보행중심가로와 젊음의 거리로부터 연계되는 입지의 변화에 따라 3.1빌딩의 저층부의 모습도 대응이 필요하게 되었다. 우리는 1층의 외부 주차공간을 과감하게 삭제하고, 선큰공간을 통해 층고가 3.3미터인 낮은 지하공간을 활성화시켰다. 또 과거 철거되었던 1층의 에스컬레이터를 재설치하여 저층부를 활성화해야 한다고 제안했다.

김중업 건축사의 아들 김희조 선생과의 만남

프로젝트 초반 3.1빌딩 건립에 참여한 김중업 건축사사무소의 일원인 김희조 선생으로부터 3.1빌딩 건축 과정에 담긴 김중업 건축사의 건축적인 고민을 들을 수 있었다. ▲건물 높이의 한계에도 불구하고 층수 31층에 맞춰 천장고를 확보하기 위해 공조실로부터 나오는 덕트를 보에 관통시켜 천장고를 확보한 노력 ▲대지의 형태에 맞춰 남측으로는 독립된 사무공간을 만들고 ▲북측으로 돌출된 작고 좁은 대지를 활용하여 사무영역과 분리된 독립된 코어를 만들어 좁은 공간에서 계단실과 승강기실, 공조실을 배치하기 위해 노력했다는 이야기를 전해 들었다. 이는 자료에서는 찾기 어려운 설계 과정의 이야기였으며, 그런 건축사의 의도를 존중하고자 했다.

시그램 빌딩과 달리 3.1빌딩의 코어는 독립 코어 형태로서 9미터 간격의 15개의 기둥과 8개의 정사각형 그리드로 이루어진 직사각형 공간이다. 오피스 영역으로부터 완전히 분리되어 있는 유니버설 디자인이 적용되어 있다. 오피스의 핵심인 코어 계획에 있어 과거 1980년도 한차례 있었던 리모델링 과정에서 탕비실과 설비공간이 오피스 공간으로 돌출되어 있었다. 우리는 이러한 평면의 형태를 복원함과 동시에 필요에 따라 늘어난 설비 공간을 콤팩트하게 코어의 사각형 틀 안에 넣고, 부족한 화장실 면적을 늘리며 승강기의 성능을 향상시켰다.

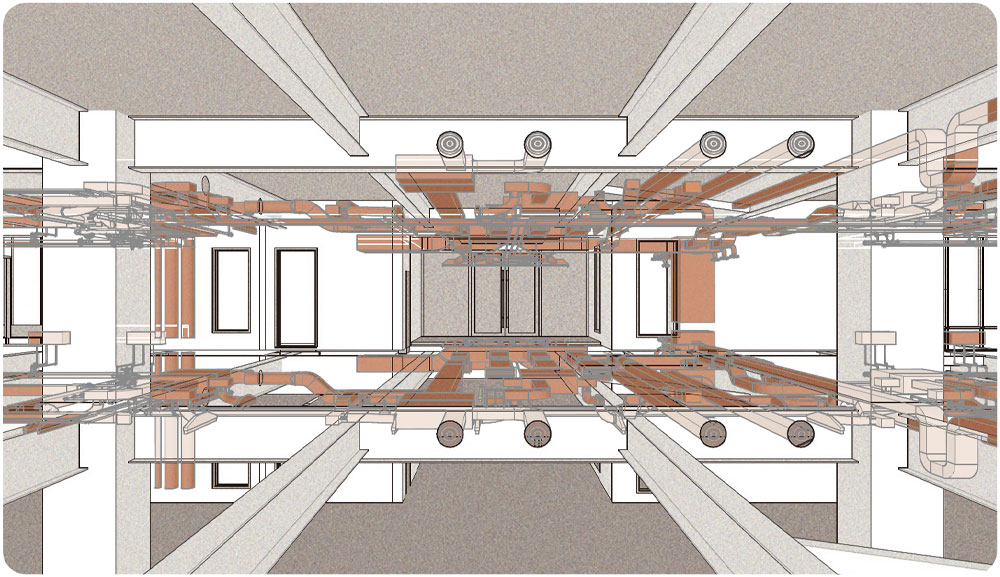

Office Level Planning

‘서울시 역사도심 기본계획 관리지침’에 따르면 31층으로 건축하기 위해 공조설비를 구조체의 일부로 소화해서 높이를 낮춘 것이 가치 있는 특징으로 꼽힌다. 즉, 층고 계획에 있어 천장고 확보를 위해 코어 내 메인 덕트를 형성하고 구조체를 관통시킴으로써 천장 속 공간의 높이를 낮추는 Honey Comb System이 적용된 것이다. 우리는 이러한 천장고를 확보하면서도 보존 대상인 허니콤보가 주는 구조미가 그대로 노출될 수 있도록 설비라인과 FCU를 공조실에서 가까운 쪽으로 배치하였으며, 기존의 허니콤보를 활용해 일부 덕트 라인은 허니콤보를 관통하도록 해 개방감을 확보했다.

커튼월의 원형 유지와 재생

땅이 가지는 역사적인 장소성과 건물의 이름처럼 3.1빌딩 건립자인 김두식은 삼일정신을 기리고 한국 사람의 손과 기술로 건물을 완성해 줄 것을 염원하였기에 한국인 건축사 김중업에게 설계를 맡겼다. 하지만, 근현대 건축자산으로서 보존대상인 철골구조와 메탈커튼월은 일본기업인 신일본제철의 코르텐 스틸이 적용되었고, 코팅재는 니혼파커라이징사의 웨더 코팅이 적용된 사실을 자료를 통해 알게 되었다. 당시 우리나라의 경제적인 상황과 기술수준으로서는 어려운 까닭에 가장 가까우면서도 선진 기술을 보유한 일본으로부터 재료와 기술을 가져와 시공해야 하는 상황이었던 것은 아이러니였기에 우리의 기술과 재료로 3.1빌딩이 재생되길 바랐다.

3.1빌딩의 커튼월의 재질은 철(Corten Steel)이다. 돌과 같이 영원히 지속되는 재료가 아니기에 세월의 흐름에 따라 손상이 누적될 수밖에 없다. 현장조사 결과 부식과 누수 구조부재의 처짐 현상 등이 일어나고 있음을 확인했다. 설계 착수 후 수행한 안전진단에서는 커튼월 외부의 코르텐 스틸 판넬과 I빔에서는 녹얼룩과 누수 현상이 상당 부분 진행되고 있음을 확인했다. 또 I빔이 수직방향으로 처짐에 따라 수평틀의 뒤틀림 현상이 다수 발생되고 이로 인해 유리의 파손이 진행되어 구조 시뮬레이션을 통해 최종적으로는 교체가 필요한 것으로 판단했다.

우리는, 당시 제조사의 제품과 국내의 커튼월 제품의 품질을 비교하고 검증하는 작업을 통해 원형을 유지하기 위한 검토를 진행했다. 노후화로 교체가 필요한 커튼월은 이번 리모델링 사업을 통해 세계 일류 건설기술을 보유한 우리나라의 기술력으로 충분히 원형보존을 전제로 한 교체가 가능하다고 확신했다.

시그램 빌딩은 부식에 강한 것으로 알려진 브론즈를 주 재료로 한 커튼월을 사용했다. 그러나 3.1빌딩의 커튼월 재료는 철(Corten Steel)이다. 재료적 특징은 잘 알려진 것처럼 안정녹을 통해 부식을 방지하는 기능을 가지고 있으며 시간이 지나며 자연스러운 색상 변화를 나타내는 재료이다. 3.1빌딩은 이런 코르텐 스틸 위에 색상 변화를 조기에 검은색으로 유지시켜 주는 웨더 코팅이라는 특수한 코팅 도료를 사용했다. 이는 당시 철강회사였던 삼미그룹의 기업 이미지를 반영하고 검은 색상을 유지하고자 한 것으로 추정된다.

시그램 빌딩의 커튼월은 유닛 공법이 적용되었다. 그에 따라 수직재와 유리 사이의 간격이 넓다. 그러나 3.1빌딩은 Stick System(Knock Down)으로 시공되어 멀리언 뒤로 프레임이 감춰져 보다 얇고 날렵한 선을 가진다. 3.1빌딩의 수직 H 형강은 커튼월의 구조재이자 루버의 역할을 하면서도 일반적인 커튼월과 달리 외부로 구조재가 돌출되어 있다. 이러한 특징은 고층건물에 있어 유지관리에 유리한 점을 지닌다. 유리를 고정하는 커버가 실내에 있으므로 유리의 파손 시 실내에서 교체가 가능하도록 고려한 것으로 보인다.

우리는 이러한 특성이 잘 보존되고 오랜 기간 유지될 수 있길 바랐기에 외부로 돌출된 H형 멀리언을 상대적으로 가볍고 저렴한 소재인 알루미늄과 같은 재질로 변경하지 않고 스틸 재질로 적용하여 본래의 수직 구조재로서의 기능과 실내에서 유리 교체가 가능하도록 설계했다.

기존의 H형강은 일본의 후지철강(지금의 신일본제철)에서 일반 구조용강제와 같은 롤빔 형태로 생산된 것으로 현재는 동일한 규격의 코르텐 스틸이 국내는 물론이고 원산지인 일본에서도 생산되지 않는 실정이었다. 국내 기업의 기술로 생산되는 내식성이 강한 스틸강종으로서 빌트업 방식(부재와 부재를 접합해 만드는 공법)을 적용했다.

또한, 기존 피복제인 웨더코팅 대신에 기존의 거칠면서도 매트한 질감을 내는 검증 가능한 코팅재(초내후성 파우더코팅)를 적용했다. 기존의 유리는 어두운 브론즈 색상에 16mm 컬러 유리가 적용되어 있었다. 기존 유리의 색상 샘플을 수집해 적용된 유리와 가장 유사한 색상을 지닌 유리를 찾아 적용하고자 했다. 기존 색상을 최대한 맞추기 위해 당시의 기술 자료를 전문가에게 의뢰한 결과 1970년대 까지는 국내에서 해당 유리를 생산할 수 없어 수입에 의존해야 했던 것을 확인할 수 있었다. 3.1빌딩보다 앞서 건축된 시그램 빌딩과 비슷한 유리가 적용되었을 것임을 착안, 당시에도 브론즈 색상 유리를 생산하던 미국의 PPG industries의 유리를 적용하기로 했다.

Earthquake-Resistant Reinforcement Structure 내진구조보강

지상 31층, 지하 2층의 3.1빌딩은 지하 2층∼지상 2층 바닥까지는 철근콘크리트 구조이며, 지상 2층 이상∼지상 31층은 철골철근콘크리트 구조로 설계·시공되었다. 코어 부위는 SLIP FORM 공법의 철근콘크리트 구조이다.

손종윤(3.1빌딩 건설당시) 삼환기업 건설본부장의 특집 기고문에 의하면, 주요자재 소요량이 철골은 2100TON, 철근은 1500TON, 시멘트 45,000포대, 콘크리트 12,000㎥로 기술되어 있다. 이런 소요량이 투입됨에도 불구하고, 당시에는 지진하중 저항을 위한 기둥 HOOP에 대한 단부 상세 기준이 제정되지 않았다.

그러나, 대수선을 진행하면서 건축구조기준(KBC2016)에 따른 내진설계 특별고려사항 기준을 충족시키기 위해서 기둥 상하단부에 연성 확보를 위한 탄소섬유 보강과 철골 거더의 횡좌굴(lateral buckling) 방지를 위한 횡지지가새가 필요하여 추가하게 되었다. (주.크로스구조 / 주.네오크로스구조 대표 김점한)

리노베이션에서의 구조설계는 정밀 구조안전진단을 통해 시작된다. 우리는 기존 골조의 안전성검토를 위해 비파괴 탐사(Ferroscan)와 골조의 피복을 뜯어내고 철근의 배근 상태 및 부식정도를 확인하여 내진보강을 진행하게 되었다.

스틸커튼월 시공과정에서의 소고

1. 3.1빌딩 입면

김중업 선생님의 3.1빌딩은 과거 당대 최고의 마천루라고 회자되었지만, 지금도 입면성, 특히 정면성을 통해서 그 존재감을 갖는다 하겠다. 주요 입면은 스틸커튼월과 유리로 국한하여 절제되고 세련된 표현으로 완성되어 자태를 뽐내지 않지만, 그곳에 서 있는 자체로 상징성을 지닌다. 반세기가 지난 지금, 시간의 흐름 속에서 입면 구성요소는 노후화되어 가고 반대로 건물 기능은 지속적으로 현대화를 요구함에 따라 결국 現 건축주는 건물을 전체적으로 리모델링하기에 이른다.

금번 3.1빌딩 리모델링에 있어서, 여러 가지 건축적 해법 등을 통한 건축적 시각과 함께 김중업 선생님의 3.1빌딩이 갖는 디자인적 가치의 구성요소들을 어떻게 보존하고 또 개선하였는지 건축문화 유산의 보존적 시각에서도 접근하는 것 또한 필요하다고 본다.

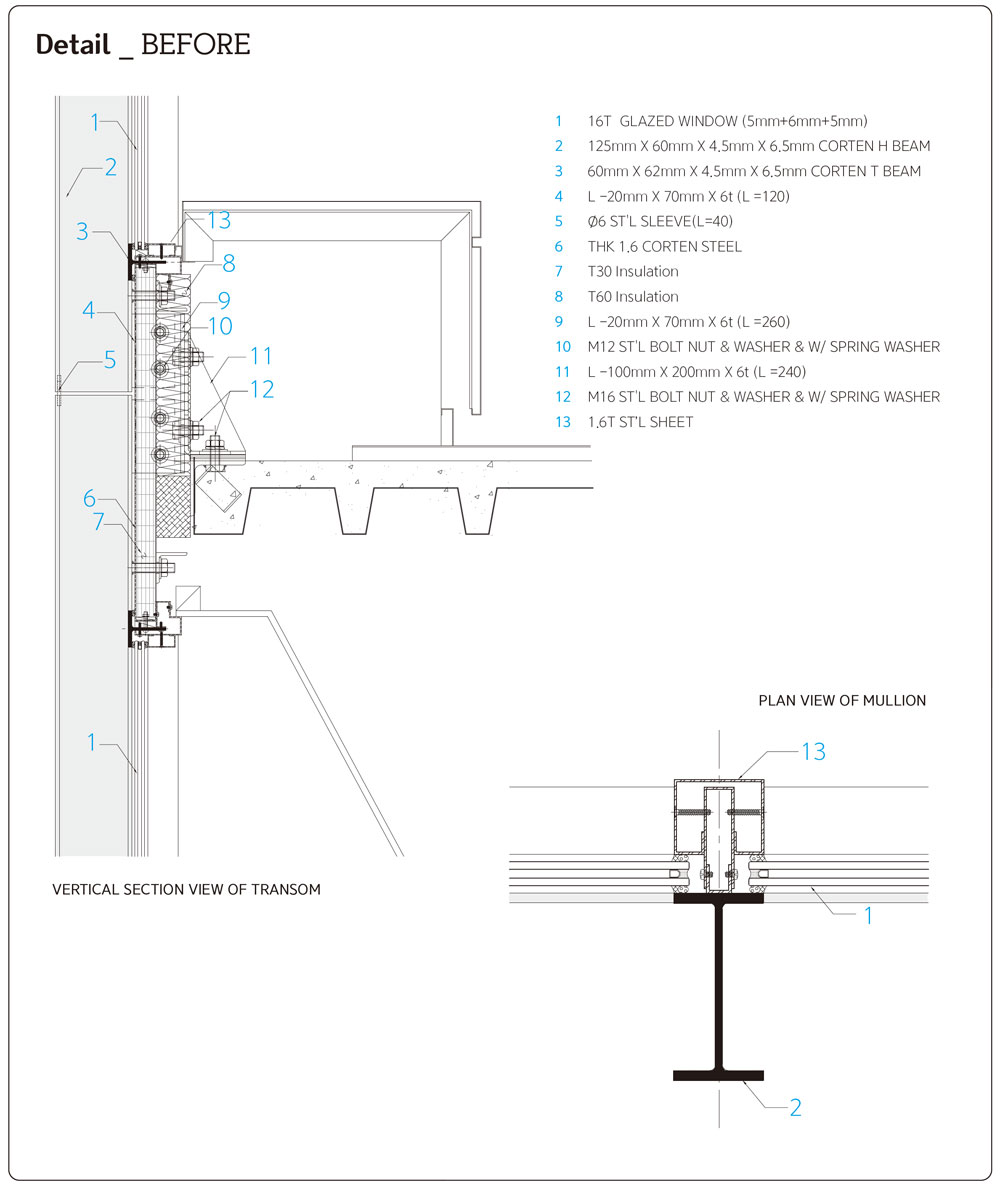

2. 3.1빌딩의 스틸커튼월 시스템 특징

기존 3.1빌딩의 커튼월시스템은 일반 AL커튼월시스템과 다르다. 외부의 스틸 I형강(코르텐스틸. 125×60×4.5×6.5)이 커튼월의 주요 구조부재이자 디자인 구성 요소로 쓰인다. 그리고 내부의 스틸 수직, 수평 부재는 유리를 고정하는 비드 역할만 하는 특이한 구조를 하고 있다. 거기에 외부 수평부재 및 스팬드럴 패널까지 코르텐스틸로 되어 있어 보기 힘든 완벽한 스틸커튼월 시스템을 이룬다. 이를 유지하고 개선하는 과정에 많은 시간과 노력을 투자하였다.

3. 스틸커튼월 부재 및 도장재

3.1 외부 I형강 대안

[日.신일본제철社.Corten.125x60x4.5x6.5 → 韓.포스코社. PosMac. 125x60x6x6]

3.1빌딩의 디자인 구성요소의 핵심인 외부 I형강은 신일본제철(日)에서 생산한 코르텐 소재의 I형강이다. 설계 당시 같은 크기의 제품은 생산되지 않아 비슷한 크기의 125x125mm 제품을 생산하여 Flange양쪽 끝단을 잘라내고 60mm의 I형강 크기만 사용하는 것을 검토하였다. 최대한 원래 소재를 찾으려 했지만, 생산 및 수입일정 그리고 생산자에 대한 문제 등으로 포기하였다. 3.1정신으로의 이끌림과 국내 기술력의 발달로 1970년대의 일본 코르텐에 대응 가능한 현재 국내 생산되는 제품으로 눈을 돌렸다. 그리하여 포스코의 PosMac이라는 소재를 찾게 되었다. 국내 통용되는 PosMac은 대부분 얇은 판재인데 포스코의 협력을 이끌어 6mm 후판을 생산하였다. 그 판재를 절단 가공하여 기존 부재와 같은 크기의 I형강을 Built Up 化 하여 만들었다. 많은 샘플 제작과 검토, 사용 경험을 바탕으로 한 해법으로 지금의 I형강을 만들었다.

3.2 도장재 대안

[日.파커라이징社.Weader Coat → 네덜란드.AkzoNobel社. 초나노분체도장재]

코르텐 철판은 처음엔 붉은색으로 녹이 발생하고 이것이 멈추어 50년 이상 되면 매트한 검은색 계열의 색상으로 최종 변한다고 한다. 최초 I형강 및 스팬드럴 패널에 칠해졌던 웨더코트는 코르텐 제품에 생산 후 바로 칠하여 50년 후의 검은색을 미리 확보한 것이다. 코르텐을 PosMac으로 대체하였듯이 도장재도 50년 전의 것보다 발전된 그에 맞는 소재를 검토하였다. AkzoNobel社의 초나노 분체도장재가 그것이다. 검은색 계열의 Matt한 색감을 완성하기 위해서 수많은 샘플 작업과 테스트를 거쳐 최고의 품질과 내구성을 갖춘 제품을 개발하여 적용하였다.

4. 스틸커튼월 설치

4.1. 커튼월 고정

기존 커튼월의 외부 구조재인 스틸 I형강을 잡아주는 화스너를 건물과 연결하는 방법은, 슬래브에 고정철물을 엠베드하고 거기에 용접을 하여 고정하는 커튼월 설치공법의 원형을 보여준다. 그러나 리뉴얼 시에는 기존 화스너를 철거해야 함에 따라 그것을 사용할 수 없었다. 또 50년 전의 부족했던 기술력과 철골 캔틸레버의 처짐, 더욱이 슬래브 끝단의 훼손 등으로 시공성을 확보하기 어려웠다. 이를 개선하기 위해 슬래브 끝단에 엠베드 철물 대신 모체앵글을 건물 외주부 전체에 수평으로 설치하고 거기에 화스너를 고정하였다. 커튼월에 작용하는 여러 하중에 따른 거동을 최소화하고 화스너의 시공성을 고려한 해법이었다.

4.2 외부 I형강 설치

3.1빌딩의 기준층 층고는 3.3m인데, 기존 커튼월 I형강 부재는 층고에 맞춘 길이로 설치되어 있었다. 커튼월 리뉴얼 시 I형강을 공기나 경제성을 감안하여 부재를 2개 층 길이로 검토하였지만, 기존의 시공적, 디자인적 가치를 이어가기 위해 기존과 같이 3.3m로 층간에서 조인트를 두고 설치하였다.

4.3 커튼월 수평부재 및 스팬드럴패널 설치

기존 커튼월의 외부 스틸수평부재와 스팬드럴 패널은 용접 및 조립되어 외기의 열전달을 차단할 수 없는 구조였다. 철거해 보니 단열이나 차수가 안 되어 부재의 부식이 심했다. 이를 개선하기 위해 리뉴얼 시에는 900mm 간격의 I형강 사이 내부에 단열 처리된 AL 수직, 수평부재를 설치하는 등 단열 및 차수를 한층 강화하였다. 외부에서는 입면 요소인 수평 스틸플랫바와 스팬드럴 패널을 설치하였다.

4.4 스틸커튼월 내부창호 설치

기존 커튼월의 내부 스틸부재는 유리를 실내에서 취부할 수 있게 하는 비드 역할을 하는 부재로 현시점에서 보면, 당시 기술력으로서는 획기적인 방법이었던 것 같다. 이 방법을 계승하고 개선하여 실내에서 세미 유닛 타입으로 공장에서 미리 만든 AL단열창호 프레임(W900XH2700)을 I형강 내부면 중앙에 이웃 창호와의 조인트를 두고 각각 고정하여 커튼월 내부 AL창호를 구성하였다.

4.5 복층유리 설치

[THK16컬러복층유리 → THK28컬러로이복층유리]

기존 유리는 그나마 브론즈 색상의 복층유리로 되어 있었지만 복층 파괴가 심했다. 유리 색상의 결정은 3.1빌딩의 얼굴색을 결정하는 중요한 부분이었다. 공사 초부터 일찍이 원형과 유사한 색상의 유리를 선정하기 위해 여러 나라의 브론즈색상 유리 샘플을 구해 비교한 끝에 PPG社의 유리를 선택하였다. 그리고 건축적 비례미의 극치인 1:3 비례(W900XH2700)의 세장한 유리 크기에 따른 만곡현상을 줄이기 위해 철저한 품질관리를 하였다. 평평한 브론즈컬러 유리면은 그 위에 돌출된 I형강이 겹쳐지면서 3.1빌딩 특유의 상징적 자태가 완성되는 데 일조하였다. 또한 복층유리 성능을 유리두께 확장, 고기능성 코팅, 단열가스 적용 등 최상으로 개선하였고, 단열간봉의 보여지는 색상까지도 I형강과 맞추는 세심한 배려도 하였다.

이렇게 개선된 유리를 건물 내부에서 먼저 설치된 AL프레임에 취부하고 마지막 AL비드로 고정하여 유리설치를 마침으로써 대단원의 스틸커튼월 시스템을 완성하였다.

5. 지속가능

많은 시간과 열정을 갖고 건축계 거장의 작품을 직접 느끼고 다듬고 고쳐서 새로이 조명된(Re-Iconize) 건축물로 재탄생 시켰다. 이러한 역사적인 사업에 참여한 것은, 건축을 하는 사람으로서 매우 영광스럽게 생각하고 그에 대한 자부심 또한 매우 크다. 이제는 열린 공간으로서의 3.1빌딩이, 익숙하지만 새로운 모습으로 그 자리를 지키고 서 있는 것이 너무 자랑스럽게 느껴진다.

지면을 빌려, 보이지 않는 곳에서 묵묵히 새로운 3.1빌딩의 재탄생에 수고해 주신 시공관계자 여러분께 감사의 인사 말씀 전하며, 3.1빌딩이 50년을 넘어 100년 이상 후대에 건축문화유산으로 전해졌으면 하는 작은 바람을 가져 본다.

Concept of the 3.1 Building

Written by. 101 Architects. Co. Ltd

1. URBAN

1-1. Recovering the frontality

The façade was planned by dividing it into a typical floor, a lower floor, and a rooftop. The typical floor maintained the existing façade of the 31 Building as much as possible while satisfying the energy and construction methods. The protruding I-beam, using the plate welding method, gave a delicate deformation. The existing R-value is invisible. The inner mullion bar adjusts the proposition (ratio) thinner and longer than the existing one to provide the I-beam's subtlety and continuous feeling. The North's core box was designed with metal panels considering the relationship between the glass curtain wall materials and modules on the front but tried to maintain the delicate front design's continuity by placing metal protruding ribs on one side of the north side. We proposed opening the side to introduce light and view to the existing elevator hall with the lack of light. But it was due to structural issues that we only applied this opening on some of the upper floors.

The rooftop needed some rooftop structures due to additional facilities, requiring a protruding structure that the existing building didn't have. The basic principle is to design by linking the existing core and mass as much as possible and setting them back from the outer wall finish to maintain the current prototype as much as possible. The material finish is planned as an aluminum louvers by taking design elements of the typical floor's vertical mullions.

1-2. Publiity and openness

Restoration of the public nature of the lower floors of the 3.1 Building is as important as the restoration of façade. Since the building worth 50 years of the past also should have future values 50 years from now on, concepts of removing barriers that had been disconnected from the world one by one and restoring publicity were needed. First, the basement floor was so low that there was no inflow of light, almost used as dead space. Considering the first-floor level, which needs to be 1.5m up, a 25m×7m line was planned based on the 3m retreat line from the front site boundary to allow underground access with minimal stairs and much brighter space. The space on the opposite side of the existing building, not on the side of the existing building, was used as a warehouse because it was lower than the current level of the first basement floor and had a long moving line. Although there was a loss of rental area through Sunken, the concept of changing the underground space was positively understood and actively accepted by the ordering agency. Space's low floor level could also improve understanding of the part proposed to be used as a restaurant while making the eye level of people looking at the outdoor landscape unusual.

In the case of the first-floor stylobate, there used to be stairs which made the whole stylobate unclear, so we found that we need a way to redesign them into a single stylobate. To integrating the sunken space, 1st-floor outer space, and base as 'one ground-scape,' we used granite (C-Rain White) that can be linked to a brightly colored floor instead of a traditional dark marble, and the rest of the sunken and 1st-floor are 1200×430-size joint method. The corners were all mixed with stones and designed with natural details, and the lighting was installed on the bottom slightly floated from the floor to lighten the details with the ground level. All of the underground air supply grills connected to the bottom of the stairs were handled in a lower stone opening method so that the opening area was not visible from the outside so that the grill did not damage the base. Also, the base's railing was planned with low iron glass so that the separation of the façade and the base was visible.

The existing façade of the 31 Building was separated from the second floor, making it difficult to secure the lower floor's openness. Therefore, the 1st floor curtain wall was removed from the outside of the beam. The facade of the 1st and 2nd floors were connected to increase openness. The second-floor transom was lowered from the floor level, making the transom line invisible to the floor when looking outside from the second-floor and keeping the Terroxy finish horizontal line clean. The three-story lower level (1st to 2nd basement floors) is designed to open up existing narrow, stuffy, and dark spaces. Several devices are intended to communicate with the outside world at the ground level.

First, the second level ceiling was designed as a light ceiling, and the low and high sections were lightly separated to maintain the original form of the existing grid design and to make the entire ceiling brighter.

Second, the long wall on the side of the lower floor's core has reflectors above it to make space expand between indoors and outdoors. To add depth to the detail, we proposed dark background above which the clear glass was installed with a certain gap to have a reflection effect.

Third, 'groundscape' is an essential keyword for 101 Architects. Although there are some aspects to consider the surrounding terrain, 'groundscape' is a concept that captures the people surrounding the building, culture, nature, history, and scenery, so we wondered it could create a new path for the next generation if space were actively opened to the ground floor. Rotating stairs connected the three floors because we wanted to make vertical movements and horizontal movements. Also, we wanted to create a cheerful atmosphere because it is a public place.

2. HISTORY _ Kim Joong-up / Mies van der Rohe

2-1. Seagram Building

If the Seagram Building had a horizontal depth in the lower level space, we tried to provide new vitality to the 3.1 Building, which was disconnected from the city by applying a vertical reinterpretation of the city's horizontal relationship due to the limitations of the narrow land and structure. Moreover, some of Mies' details were borrowed, with a new interpretation of the low-floor exterior finishing with marble into metal and glass curtain walls. The design elements were I-beams for the details of the column section and the C-shape angle for the windshield section, so that the lower layer and the typical floor could lead to a single design language when viewed from the outside.

2-2. Heritage

As a modern cultural heritage, the Heritage Site for the 3.1 Building is designed as an essential architectural and interior elements of the lower floor.

First, the circular staircase's void space made the circular concrete structure naturally exposed without finishing the slab cross-section and two columns around the remaining beams, making it look natural without any difference with new finishes. Second, part of the existing curtain wall was designed at the first-floor entrance, allowing people to see the curtain wall, a symbol of the 3.1 building, at the level of people's eyes. Finally, the completion stone 50 years ago and the current completion stone were placed side by side to show the history at one sight.

3. RENOVATION

3-1. Typical Floor

The dedicated space's biggest concern was the design of elevating the floor height and the relationship with the other factors derived from it. First of all, it was divided into perimeter columns and internal columns. We wanted to make the perimeter column open to see uniform lighting from the outside. In conjunction with the core, we proposed the inner column plan some ceilings to concentrate the facilities as much as possible to install conference rooms or partition walls later. The relationship with other elements was resolved in several details below.

First, the relationship between curtain walls and ceiling is established by planning only the minimum ceiling for curtain boxes meeting with curtain walls.

Second, the light on the exposed ceiling is planned every 1,800mm based on the curtain wall interval (900mm), and the sprinkler is designed as one with the light to maintain the maximum openness of the ceiling. In the case of lighting, adjust the separation distance from the curtain wall to be seen the same from the outside.

Third, the lower part's ceiling is planned, aligned with the exposed portion's lighting line, and the diffuser plan is integrated.

The ceiling's exposure color was toned in dark colors, taking into account the spatiality of the curtain wall, and then carefully controlled the entire tone by adjusting the columns, walls, low ceilings, and exposure lights to white and bright, warm beige tones. Also, the public space was designed as a reflector on the north side to ensure openness with the same reflection effect as the lower level.

3-2. Lower Floor

The lower floor was planned in a continuous relationship between the outer space and the typical floor, and the plan to restore the location of the escalator to the second floor, create an anchor tenant(main shop) on the first floor, and connect the three floors vertically became the starting point.

For ceilings, lower level columns and curtain wall baselines were created based on the typical floor curtain wall line, and the ceiling design was completed by creating a 1.8 m×1.8 m grid according to the line. The first and second-floor ceilings are the same size. Still, the second floor has two designs in one grid, with the grid surface itself becoming a light ceiling and the border is made of diffusers, while the first floor's edges are lighting and the surface is made of sound-absorbing material. This plan is a reinterpretation of the existing 3.1 building and the Mies' grid lighting, and both floors are designed to create a flat surface to ensure openness and install sprinklers and detectors at the grid intersection to create a unified ceiling design.

The floor is terrazzo using a field grinding method, similar to the outer granite's tone, with a single wide plane without a frame expanding from the outside. The walls were also planned in the same fashion, consisting of flatness in response to the ceiling's linear elements and curtain walls. The top of the wall was designed with glass reflectors, and the inner columns were planned with metal reflectors to ensure uniformity and openness.

The circular staircase proposed a design that interpreted the iron plate's structure and revealed the opening and structural beauty by showing bumps on the stair floor without any special finishing. The circular staircase's opening was with a low iron glass railing, allowing clear visibility from inside and outside.

31 Building Renovation_ Preserving the original form of 31 Building,

the symbol of modernization and rebirth as a sustainable landmark tower

Written by. Junglim Architecture Co. Ltd

3.1 Building, which was completed in 1970 and has been located in Gwancheol-dong for more than 50 years, was not enough to compete with the contemporary office-grade due to aging. Nevertheless, the 3.1 Building is one of the few buildings with a large floor area ratio in Seoul, and it has an attractive property value that cannot be explained. It is a building containing the symbolism that penetrated our modernization period for a long time with numerous tales. Many tales have been made about the building, including the symbol of modernization, modern and contemporary architectural assets, the work of a master named Kim Joong-up, Korea's first skyscraper, and the tale of the Seagram Building, which became the motif of the 31 building. The tale of the building, which is about 50 years old, is that powerful.

The project began hoping that the aged beauty of the 3.1 Building will be renovated into a modern design while reborn as a new building with the functions required by the contemporary office and a unique place in Jongno, central Korea. The current 3.1 Building shows that many people who participated in the renovation project and the architect's eye recognition of the building's unique charm.

3.1 Building, which was completed in 1970, was the tallest in Korea until the 63 Building was built in Yeouido 15 years later. Still, it was gradually forgotten in our memory as the aging of facilities progressed rapidly more than 50 years later. We found the possibility of the rebirth of the 3.1 Building in Cheonggye Pass's sight, a symbol of modernization, disappearing, and the surrounding streets changing. In other words, we followed the footsteps of architect Kim Joong-up and discovered the value contained in the 3.1 Building and tried to regain its past reputation as a 'sustainable building as much as the time passed while keeping the original form.'

Reading of site_Demolishing the Cheonggye Overpass

Compared to when the 3.1 Building was built, the most different part is Cheonggyecheon Stream. When selecting the location of the 3.1 Building, many people suggested the southern part of the Han River as the best place (now Gangnam). However, Kim Doo-Sik (the founder of 3.1 Building) said that the current location would be the center of transportation due to Cheonggye Overpass's construction and the construction of subway line 1. 3.1 Building, the tallest building in Korea at the time of its completion, was the most representative landmark of Jongno-gu along with Sewoon Shopping Center and Cheonggye Overpass. The most crucial factor in selecting the current location was the Cheonggye Overpass.

However, with the demolition of Cheonggye Overpass and the restoration of Cheonggyecheon Stream, the lower level of the 3.1 Building should also react to the change in the pedestrian center's location and youth streets the past and modern coexist. We boldly deleted the outer parking space on the first floor and activated the underground space with a floor height of 3.3 meters through the sunken space. We also suggested that first-floor escalators, which had been demolished in the past, should be reinstalled to activate lower floors.

Meeting with Kim Hee-jo,

the son of the architect Kim Joong-up

We were able to hear the architectural concerns of Kim Joong-up from Kim Hee-Jo, a member of the Kim Joong-Up Architects Office who participated in the construction of the 31 Building at the beginning. ▲ Despite the limitations of the building's height, the efforts to secure the ceiling height by penetrating ducts from the air conditioning room to the 31st floor ▲ Created an independent office space in the south ▲ Created a separate core from the office area. This story of the design process was difficult to find in any data, and we tried to respect such an intention of the architect.

Unlike the Seagram Building, the core of the 31 Building is an independent core, rectangular space consisting of 15 columns and 8 square grids at intervals of 9 meters. It has a universal design that is completely separated from the office area. In core planning, which is the core of the office, the office pantry and facility space were protruding into the office space during the remodeling process that took place once in 1980. We restored the shape of these planes while simultaneously placing the increased facility space as needed into a compact square frame of the core, increasing the insufficient toilet area and improving the lift's performance.

Office Level Planning

According to the Seoul Metropolitan Government's Basic Plan Management Guidelines', it is considered a valuable feature that the air conditioning facilities are designed to build on the 31st floor. In other words, the Honey Comb System is applied to reduce the height of the space in the ceiling by forming a main duct in the core and penetrating the structure to secure the ceiling height in the floor plan. While ensuring this ceiling height, we placed the facility line and FCU close to the air conditioning room. Honey Comb's structure, which is the subject of preservation, can be exposed, and some duct lines can penetrate Honey Comb to secure openness.

Maintaining the original shape of curtain wall

and renovation

Like the historical place of the land and the name of the building, Kim Doo-Sik, the founder of the 3.1 Building, left the design to Korean architect Kim Joong-up because he wanted to honor the spirit of 3.1 and complete the building with Korean hands and technology. However, data showed that the steel structure and metal curtain wall, which are conserved as modern and contemporary architectural assets, used Japanese company Nippon Steel's Corten Steel. The coating material was applied with a weather coating by Nihon Parkerizing. At that time, it was ironic that they had to bring materials and technologies from Japan, which is the closest to Korea's economic situation and technology level, and had to build them, so we hoped the 3.1 building would be regenerated with Korean technology and materials.

The curtain wall of the 3.1 Building is made of corten steel. Since it is not a material that lasts forever, like a stone, the damage will inevitably accumulate over time. On-site investigation confirmed that corrosion and sagging of water leakage structural components were occurring. After the start of the design, the safety diagnosis confirmed that much of the rusting and leakage phenomena are underway on the Corten Steel Panel and I-Beam outside the curtain wall. Also, as the I-beam droops vertically, many warping occurred in the horizontal frame, which led to the glass breakage, which eventually required replacement through structural simulation.

We conducted a review to maintain the original form by comparing and verified the manufacturer's products' quality at that time and domestic curtain wall products. Curtain Wall, which needs to be replaced due to aging, was convinced that the remodeling project could be replaced on the premise of preservation of circularity with Korea's technology with the world's leading construction technology.

Seagram Building used a curtain wall with bronze, which is known to be corrosion resistant. However, the curtain wall material of the 3.1 Building is corten steel. As is well known, material features can prevent decay through stable rust and are materials that show natural color changes over time. 3.1 building used a special coating paint called weather coating, which kept color changes black early on the corten steel. It is believed that the company wanted to reflect the image of Sammi Group, which was a steel company at the time and maintain its black color.

The curtain wall of the Seagram building was applied with the unit method. The gap between the vertical material and the glass is wide accordingly. However, the 3.1 Building was constructed with the Stick System (Knock Down), and the frame was hidden behind the mullion, making it thinner and sleeker. The vertical H steel of the 31 Building is the curtain wall's structural material and serves as louvers, but unlike the general curtain wall, the structural material protrudes outward. These features have advantages to maintenance in high-rise buildings. Since the glass cover is installed indoor to replace inside in the event of damage to the glass.

We hope that these properties be well preserved and long-lasting. We designed the extruded H-type mullions with steel materials as the vertical structural elements, not with relatively light and inexpensive aluminum materials.

The existing H-shaped steel was produced in the same roll beam form as general structural steel at Fuji Steel in Japan (now Nippon Steel), and the same standard of corten steel was not produced not only in Korea but also in Japan. We applied a build-up method (construction method made by combining components) as a highly corrosion-resistant steel produced by Korean companies' technologies.

Also, verifiable coating materials (super-durable powder coating) that produce conventional rough yet matte textures were applied instead of weather coating, which is an existing coating material. The existing glass was dark bronze with 16mm colored glass. It was intended to collect color samples of existing glass and find and apply glass with the most similar color to applied glass. To match the existing color as much as possible, we requested the technical data experts on the existing condition. It was confirmed that they had to rely on imports because they could not produce the glass in Korea until the 1970s. The glass was similar to the Seagram Building, which was built earlier than the 3.1 Building. PPG Industries of the United States produced bronze-colored glass at the time. We decided to apply it.

Controlling facade using internal line lighting. On the façade of the 3.1 Building, various functions with contemporary technology were added. Automative roll screen is controlled by a central control system, and the height is automatically managed following the solar radiation quantity. Moreover, a controlling function was added to internal line lighting in order to produce various spectacles.

Earthquake-Resistant Reinforcement Structure

3.1 Building with 31 stories above ground and two stories below ground has a reinforced concrete structure from 2 levels below ground to 2 stories above ground, and 31 stories above ground have been designed and constructed in a steel-reinforced concrete structure. The core area is the reinforced concrete structure of the slip form method.

According to an exceptional contribution by Son Jong-Yoon, head of Junglim Architecture Construction Division, the main material requirement is 2,100 TON for steel, 1,500 TON for steel bars, 45,000 bags of cement, and 12,000㎥ of concrete. Despite these requirements, the detailed end-to-end standards for column HOOPs for seismic load resistance were not established at that time.

However, to meet the criteria for building construction following the Building Structural Standards (KBC2016), the column's upper and lower parts needed carbon fiber reinforcement to secure flexibility and cross-fertilization to prevent lateral buckling of steel girders. (Cross Structural Consultant Co., LTD. CEO Kim Jeom-Han)

While minimizing the burden of the existing structure during the renovation process, we had to increase the design's completeness. The design was carried out by considering overall loads such as the sunken garden, exterior wall opening, load on rooftop structures and equipment, examining existing structural data and structural status at the site, and checking one by one.

Reading of Steel Curtain wall

3.1 Building has a significant value on façade (especially frontality). The façade is completed with a steel curtain wall (from now on, curtain wall) and an understatement limited to glass, which also reveals symbolism. In this article, I will briefly explain how we renewed the curtain wall, which is the most important of the various values of the remodeled 3.1 Building, and outlines how we inherited and improved the past in the process.

Steel curtain wall system of 31 Building

The curtain wall system of the existing 31 Building is different from the regular AL curtain wall system. External Type I steel (Corten. 125X60X4.5X6.5) is the main structural component of the curtain wall and the design element. The interior vertical, horizontal member is a unique structure that only serves as a bead to hold the glass. The outer horizontal component and the spandrel panel are made of corten steel to form a complete steel curtain wall system. Through this renewal, the materials of the aging curtain wall system were replaced and improved in time.

Installing steel curtain wall

1) Installing embedded plate fixing curtain wall fastener

Combining the I steel fixing fasteners of the existing 3.1 building shows the prototype of the curtain wall installation method by embedding the fixed hardware on the slab and welded it there. However, the existing fasteners had to be removed for renewal, so they could not be used. Due to the lack of technology 50 years ago, the sagging steel cantilever, and even more damage to the slab end, it was challenging to guarantee the construction's performance. To improve it, the curtain wall's outer slab end was horizontally reinforced, then the fasteners were installed.

2) Installing exterior I steel

The typical floor height of the 31 Building is 3.3m, and the existing curtain wall I steel was installed in a length that was tailored to the floor's height. Improved I steel (Posmac 125X60X6X6) when renewing the curtain wall and two-layer sizes were considered for air and economy but were installed between 3.3m floors to continue the existing constructive design value.

3) Curtain wall horizontal component and installing spandrel panel

The horizontal component of the existing curtain wall and the spandrel panel were installed as an integral part, making it vulnerable to insulation and leakage. To improve this, the inner AL insulated horizontal component and the spandrel panel were installed separately between the 900mm gap between the outer I steel to enhance insulation and water quality, and a horizontal steel flat bar, a façade element, was installed from the outside.

4) Installing interior steel curtain wall windows

The steel component inside the existing curtain wall serves as a bead that allows glass to be handled indoors, and at this point, it seems to have been a groundbreaking method for technology at the time. Subsequent and improved to this, the factory-made AL window frame (W900XH2700) in semi-unit type indoors is fixed respectively with a continuous window joint at the center of the I-beam inner face, forming an AL window inside the curtain wall.

5) Installing glass

The improved double-layer glass (THK16-color double-layer glass → THK28-color double-layer glass) was installed indoors in the AL frame and fixed with an AL bead to complete the glass installation to complete a large-scale steel curtain wall system.

Conclusion

We directly felt, refined, and modified the building to be reborn as a newly illuminated, Re-Iconized masterpiece of the master of the architecture. Participating in this historical project is a great honor and pride as an architect. The 31 Building as an open space is familiar, but I feel proud of standing there with a new look.

I would also like to thank construction officials for their effort to rebirth the new 31 building in an invisible place and hope that the 31 building will be passed on as an architectural heritage in the future for more than 50 years.

| 3.1빌딩 리노베이션 건축주 | SK D&D(주), 벤탈그린오크, 이지스자산운용(주) CM | (주)정림건축종합건축사사무소 설계팀 | 정림건축 _ 김해진, 김현삼, 조성원, 손동기, 김재현, 김정연, 박재완, 전상우, 정목조 원오원아키텍스 _ 최준우, 박슬기, 정재원 CM팀 | 안인석, 김성식, 김선식 시공사 | (주)KCC건설 대지위치 | 서울특별시 종로구 청계천로85 주요용도 | 업무시설, 근린생활시설 대지면적 | 1,877.40㎡ 건축면적 | 1,090.58㎡ 연면적 | 35,010.61㎡ 건폐율 | 58.09% 용적률 | 1,704.87% 규모 | 지하 2층, 지상 31층 구조 | 철골조, 철근콘크리트조 외부마감재 | THK28컬러로이복층유리, 스틸커튼월, AL복합패널 내부마감재 | 테라조타일, OA Floor+카펫타일, 노출천장 위 페인트 설계기간 | 2018. 03 - 2019. 03 공사기간 | 2019. 05 - 2020. 09 사진 | 윤준환, 장미 구조분야 : (주)네오크로스구조엔지니어링 기계설비분야 : (주)정도설비 전기분야 :(주)나라기술단 방분야 : (주)남도소방 |

SAMIL BUILDING RENOVATION Client | SK D&D / Bentall Green Oak / IGIS Asset Management CM | JUNGLIM ARCHITECTURE Project team | ONE O ONE _ Choi, Joonwoo / Park, Sulgi / Chung, Jaewon JUNGLIM _ Kim, Haejin / Kim, Hyunsam / Cho, Sungwon / Son, Dongki / Kim, Jaehyun / Kim, Jungyeon / Park, Jaewan / Jeon, Sangwoo / Chung, Mokjo CM team | Ahn, Inseok / Kim, Seongsik / Kim, Seonsik Construction | KCC E&C Location | 85, Cheonggyecheon-ro, Jongno-gu, Seoul, Korea Program | Business, Neighbourhood facility Site area | 1,877.40㎡ Building area | 1,090.58㎡ Gross floor area | 35,010.61㎡ Building to land ratio | 58.09% Floor area ratio | 1,704.87% Building scope | B2F - 31F Structure | Steel, RC Exterior finishing | Thk28 Color Low-e Pair Glass, Steel Curtain wall System, AL composite panels Interior finishing | Terrazzo tile , OA Floor+Carpet tile, Exposed ceiling paint Design period | Mar. 2018 - Mar. 2019 Construction period | May 2019 - Sep. 2020 Photograph | Yoon, Joonhwan / Jang, Mi Structural engineer | Neocross Structure Mechanical engineer | Jungdo ENG Electrical engineer | Nara ENG Fire engineer | Namdo TEC |

'회원작품 | Projects > Office' 카테고리의 다른 글

| 이원의료재단 송도의학연구소 2021.11 (0) | 2023.02.13 |

|---|---|

| 지타워 2021.5 (0) | 2023.02.03 |

| 모제림 모발이식센터 리노베이션 2020.10 (0) | 2023.01.25 |

| 마곡 퀸즈파크13(마곡 C12-8,16) 2020.7 (0) | 2023.01.17 |

| 클리오 사옥 2020.6 (0) | 2023.01.16 |